JANUARY 30, 2024

5 Ways to Get Your Sustainable Thermal Packaging Strategy Right

The phrase – it takes a village – is an understatement as it applies to sustainability for a multi-national pharmaceutical company.

First, there is no such thing as a sustainable free lunch. There are competing interests in packaging sustainability that must be balanced, especially when you start unfolding the entire lifecycle of your packaging.

However! We are in it together. There are so many initiatives and partners forging sustainability paths using data as their guide. Suppliers’ actions to lower carbon emissions across the value chain impact all our Scope 3 emissions.

No matter where you are on your sustainability journey, please consider these 5 important lessons we’ve learned working with pharmaceutical customers globally.

1. Decarbonization and Scope 3 reductions don’t start at end-of-life.

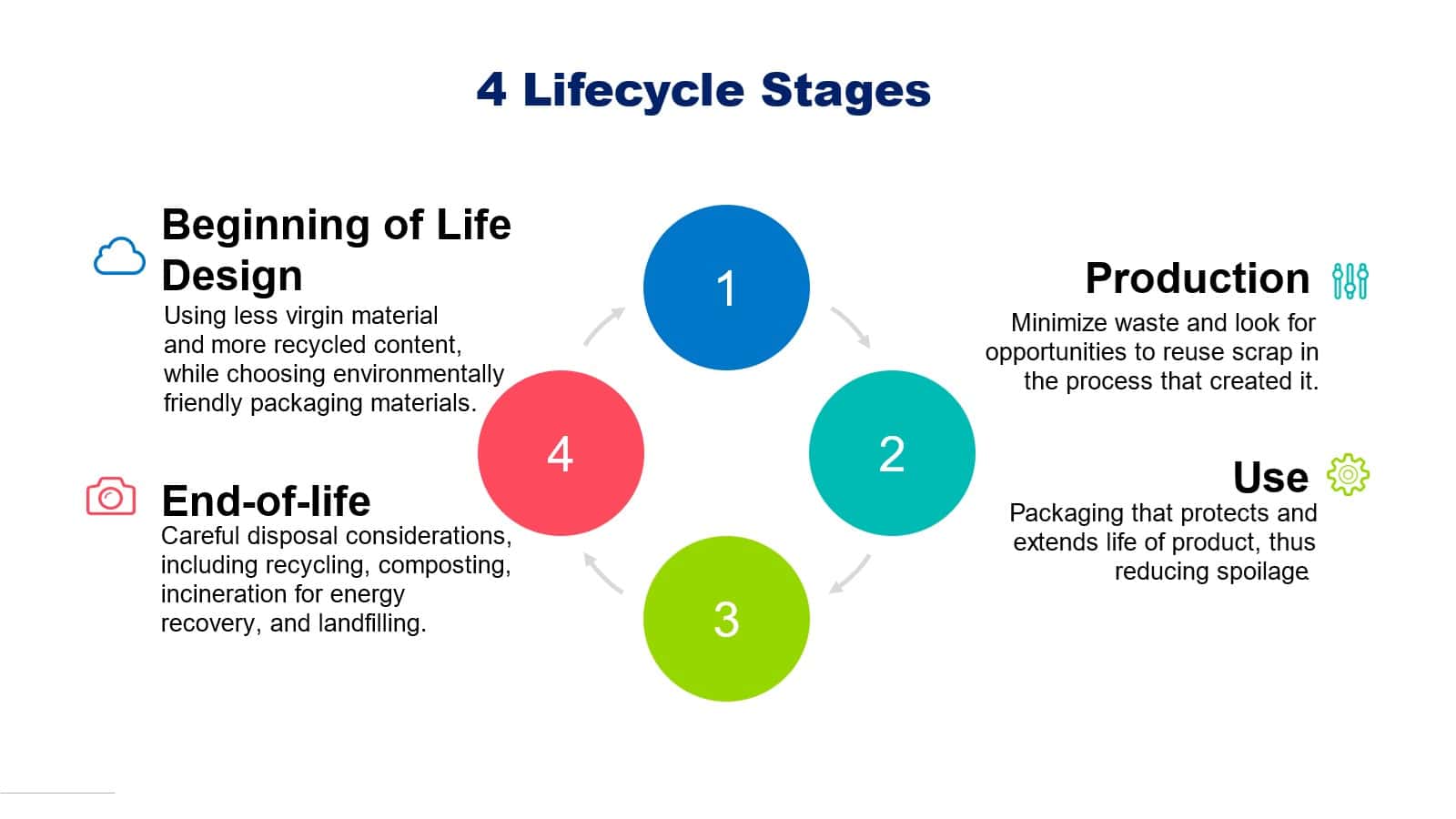

Evaluating and understanding how a shipper is managed after its use is crucial, but most environmental impact is built into the materials and manufacturing. Sustainability needs to start at the beginning. During R&D and design, packaging engineers are critically evaluating new sustainable materials with advantages that can be passed along to customers. Environmental impacts need to be evaluated from cradle to grave: raw materials, manufacturing, transportation, and end-of-life. Sonoco ThermoSafe is proud to be a material neutral partner offering science-backed material choices to include more reusable and recyclable materials informed through life cycle assessment and similar methodologies.

“One of the primary challenges is gaining a comprehensive understanding of the environmental impact of the existing packaging, one metric being carbon footprint. This entails assessing the entire life cycle of the packaging, from raw material extraction and production to distribution, use, and disposal. Many organizations struggle with collecting accurate and detailed data throughout the supply chain. This challenge can be addressed by using life cycle assessment tools and collaborating with forward-acting suppliers and partners to obtain the necessary data”.

Alison Crawley – Global Sustainability Manager, Sonoco ThermoSafe

2. Look beyond just recyclable packaging.

Recyclable packaging has made headway in achieving sustainability goals and is a good solution for last mile such as clinics, pharmacies, and patient deliveries. However, there are performance limitations in length of shipping time and sub-zero cold shipments. Alternatively, reusable rental parcel systems have very robust performance and offer additional benefits in reducing pharmaceutical company’s operational complexities, cost, labour and significantly contributing to reduction of waste and CO2 emissions.

Although it’s important to remember – there isn’t just one ‘magic material’ that’s going to solve the sustainable packaging puzzle. Rather, it’s a cumulative effect of many small decisions. For example, choosing paper-based curbside

3. Leverage data technology to uncover sustainability gains in your supply chain.

Pulling in shipment visibility, temperature and other data points is vastly critical to proving quality control of medicinal products and safe delivery of your high-value products, while at the same time cutting lost revenue due to spoiled products.

Real-time shipment tracking data should be used to minimize spoilage and avoid thermal packaging ending up in a landfill. Avoiding spoilage is critical, but sometimes this leads to over-engineering and ultimately more packaging, that isn’t necessarily needed. Evaluate your risk management data to find the balance between product protection, material utilization, and sustainability.

4. Implement a supplier assessment to align their activities to your sustainability efforts.

Audits are a common practice across the pharmaceutical value chain – it’s no different for sustainability. Take a discerning approach to narrowing down the supplier assessment questions, metrics and scoring scale.

Challenge your partners. Set the bar exactly where your pharmaceutical organization wants to go.

5. Establish clear metrics and goals with your partners.

Not easy! Why? Because the data isn’t available, either from internal stakeholders or partners, or it’s hard to piece together the data to make measurable sense. Building credible data across multiple sources to create a complete picture of your CO2 emissions, waste or other sustainability metrics is the goal.

The only way to do this – like anything else in supply chain – is in collaboration with strategic partners that have the resources, knowledge, and commitment to sustainability.

Don’t forget!

Sustainability can mean different things at different times in a packaging lifecycle and a company’s journey. EACH lifecycle phase and packaging design is important for you and your packaging partner to consider where sustainability gains can be made.

Learn more!

To dig further into the topic of how to dissect sustainability in your healthcare supply chain, watch Sustainability 101 on-demand webinar presentation.

Keep Learning

Also! Sonoco ThermoSafe collaborated with the LogiPharma WBR Insights Team on a new eye-opening Sustainability Industry Report. 150 Heads of Supply Chain and similar senior executives from the life sciences industry across Europe were interviewed by phone about the challenges they face in achieving their sustainability targets and the solutions being brought to the table. Read more about the report and download your own complete copy.

Access the Sustainability Report

Learn how exactly Sonoco ThermoSafe reduces Scope 1, 2, 3 emissions across our operations and business, aligned to SBTi. Sonoco has been awarded the Silver Ecovadis rating , as well as other notable Sustainability accolades, consistently year after year. Most recently, Sonoco was the sole thermal packaging manufacturer to be named on USA Today’s list of America’s Climate Leaders 2023. Learn more about how Sonoco’s reports annually into multiple standard setting bodies and indexes that prove Sonoco’s actions and commitments to sustainability.

All about Sonoco ThermoSafe Sustainability